-

PRODUCTS

-

- BIOMASS POWER GENERATION

- Combined Heat & Power Systems

- Electrical Power Generation Systems

- BIOMASS ENERGY SYSTEMS

- Steam Boiler Systems

- Thermal Oil Heating Systems

- Direct Fired Heating Systems

- FUEL STORAGE & HANDLING

- Fuel Storage Bins

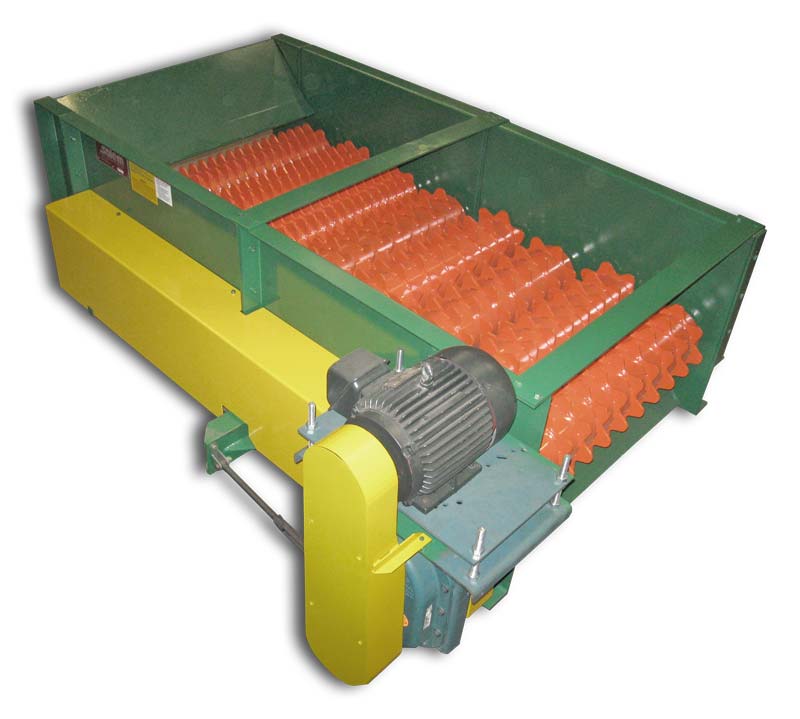

- Live Floor Fuel Bunkers

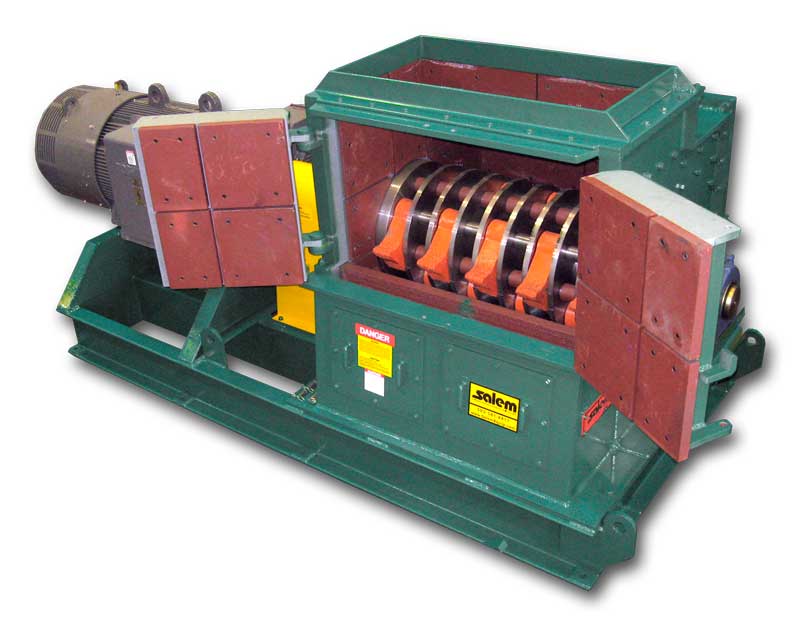

- Fuel Preparation, Conveying & Handling Systems

- ENVIRONMENTAL PROTECTION SYSTEMS

- Electrostatic Precipitators (Particulate Control)

- SNCR (Nox Control)

- Continuous Emissions Monitoring (CEMs)

- DRY KILN SYSTEMS

- Double & Single Track Kilns

- High Temperature (SYP) Kilns

- Continuous Dry Kilns

- Package Kilns

- SYSTEM CONTROLS

- Lumber Dry Kiln Multizone Control (CMZ)

- Moisture Metering Systems

- Boiler System Control Upgrade

-

-

PROJECT SERVICES

-

- PROJECT SERVICES

- Installation

- Engineering & Design

- Procurement

- Training

-

-

CUSTOMER SUPPORT

-

- CUSTOMER SERVICE

- Technical Support

- Outage Services

- System Calibration

- System Tuning

- Online Help Services

- Site Evaluations

- PARTS

- Sales & Support

- Upgrades

- REFRACTORY SERVICES

- Refractory Repair

- Replacement

- Installation

- KILN & LUMBER DRYING SERVICES

- TRUMARK Training

- Drying Schedule Support

- Site Evaluations

-

- NEWS

- ABOUT

- CONTACT